Warning 3d printed parts may break and be a choking hazard for young children. Many glues are also toxic, you take responsibility for what you print….

PETG preferred material

“hot melt” glue used throughout

Duplo is annoying to print as an exact friction fit is required. Experiment with a small part ie (S1 or P3) and check for fit.

If too loose you can try: over extruding a little, if the holes are too loose (they are generally on the bottom of the part as printed) so squashing the bottom layers a bit can help (ie have a 0.1mm gap but have slicer set for 0.3), again for the holes you can try printing with supports / brim or raft and not cleaning these up completely afterwards.

If too tight you can try mechanical means to remove excess (sanding, drilling, reaming, cutting a few prongs off) you could try underextruding a little.

For more unexpected results you could try resizing the part a tiny bit or changing the accuracy on your slicer.

Anyway probably worth making sure your 3d printed duplo fits before spending days printing…

Printing / construction advice

Turbo fan jet (J1, J2, J3)

Print in orientation shown in file, I used a brim for jet parts as they are pretty tall with a small base.

Glue parts together in a common sense way

Internal jet (intake / exhaust parts – IJ1, IJ2, IJ3)

IJ2 is used for both intake and exhaust

Print intake IJ1 on an angle so its front rests on the build plate. Print IJ3 in its end

Print 2 IJ2’s and glue IJ1 and 2 into them

Propeller (P1, P2, P3)

Print in orientation shown, other than propeller – print this flat side down

It is difficult to print the slot on the propeller (P2) to accept nose cone well (P1). It is oversized but still needed a knife / engraving tool to clean it up so the parts could fit, if you have a working cooling fan this would likely help

Yes the propeller attachment is sloppy, but at least it spins easily, you make this more accurate and remix if you want

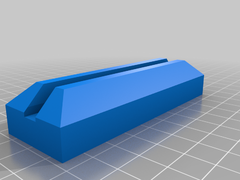

Wing tilter for swept wings (S1)

Print as shown, just make 4 as you tend to need to clamp the wing from above and below for it to hold properly

Tail (T1, T2)

Print in orientation provided. I found the holes on the base a little narrow. But these could be loosed by shoving a few duplo prongs in at a time and doing this lots of times (did end up just jamming a 6×2 original duplo bit onto the bottom and it just stays there

Undercarriage Wheel (W1, W2, W3)

Print in orientation provided, mirror W2 in slicer and print one normal and one mirrored W2

To hold the wheel on use some M3 bolts with their heads cut off. You may need to screw them in on one side W3 and drill out on the other W2 to spin easily.

Assemble in common se

This article was first featured at https://ift.tt/2UDWbUJ on April 3, 2020 at 09:08PM by MrPrinterHacker

More Stories

Can this possibly be true? “Metal 3D printing is now possible on any 3D printer…with the right settings and a few minor upgrades like a hardened steel nozzle…” – July 2 2023 at 04:59PM

New NASA Funding Ignites 25 3D Printing Projects in Space Exploration – June 18 2023 at 04:34PM

Nvidia AI produces 3D models from 2D videos 3D printing applications forthcoming? – June 15 2023 at 02:55AM