This is a really simple tool that I’ve found useful in eliminating some messing around when designing something to fit a physical object with a given amount of slack.

For example, say you have a metal rod or a hex bit from a drill that you want to “fit” into your 3D printed object. You measure the item with calipers, which gives you the size for the design, but you’re not too sure what the actual “fit” will be like when it’s printed out.

Sometimes you want a loose fit, which will be loose enough to allow the item to slide freely, but not so loose that it will wobble around in the hole. Sometimes you want a tight fit, so the item will go into the hole, but not come loose without some small amount of force (like the “grip ” between Lego bricks). And sometimes, as with screws, you want it to be small enough that the item won’t quite fit into the hole, but the hole is large enough to allow the screw to “bite” into the plastic without destroying things in the process.

I generally have a “feel” for these tolerances now with my printer, but these blocks give a really quick way to test and have some peace of mind, and real confidence that the printed item is going to do the job.

The OpenSCAD file allows the generation of blocks of arbitrary sizes, though the provided STL files will probably meet most needs.

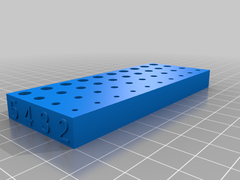

Each row of 10 holes has a label at the end which indicates the “base” size in mm for the holes of that row. Each hole is 0.1mm larger than the one to the left, starting at 0.0mm larger (i.e., the “base” size) and going up to 0.9mm larger at the right hand end.

By messing with the parameters in the OpenSCAD file, you can quickly generate a custom blocks with rows of the desired thickness, hole size, and number of sides for the holes.

Some notes if you’re using the OpenSCAD to create your own blocks:

- I’d avoid going crazy and printing a single block that does every hole size between 0mm and 15mm; it will take ages to print, and you’ll use up unnecessary filament because of the spacing around the holes. Four rows in a block is probably as far as you want to push it for print time and effective use of your roll of plastic.

- You can customise the number of sides for the holes with the – you’ll probably just want circles or hexagons, but if you want you can do triangles or octagons or whatever you like. Just bear in mind that it’s the hole diameter you’re working with, so if you do squares with a diameter of 5mm, you won’t get squares with 5mm sides, you’ll get squares which are 5mm diagonally between opposite corners (the diameter of the circle which would contain the square).

This article was first featured at https://www.thingiverse.com/thing:4348650 on May 9, 2020 at 01:22AM by adlaws

More Stories

Can this possibly be true? “Metal 3D printing is now possible on any 3D printer…with the right settings and a few minor upgrades like a hardened steel nozzle…” – July 2 2023 at 04:59PM

New NASA Funding Ignites 25 3D Printing Projects in Space Exploration – June 18 2023 at 04:34PM

Nvidia AI produces 3D models from 2D videos 3D printing applications forthcoming? – June 15 2023 at 02:55AM