ABS Snap Together Monomer

Background & Chemistry

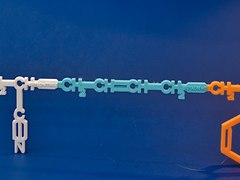

ABS is a terpolymer composed of the three diferent monomers: Acrylonitrile, Butadiene and Styrene. The resulting polymer gets it’s stiffness from the Acylonitrile and Styrene, and it’s toughness from Butadiene. The ratio of these three components can be varied to tune the mechanical properties of the polymer.

3D Model

This model is a stylized representation of how the three ABS monomers is typically drawn on a flat sheet of paper. It is also possible to make Polystyrene (PS) and Polybutadiene (BR-Butadiene Rubber) by linking one type of monomer. It is worth noting that Polybutadiene rubber is typically vulcanized which creates crosslinks between the linear polymer chains, which cannot be represented with this model. It is also possible to make Polyacrylonitrile (PAN) as well, but this polymer is not typicall used on its own. The common copolymers Styrene Acrylonitrile (SAN) and Syrene Butadiene Rubber (SBR) by combining the two respective monomers.

3D Printing and settings

This model is designed to be printed without supports. The text is designed to be printed with a 0.4mm nozzle. Any number of walls and infill % should work, but if you intend to chain a large number of monomers together adding additions wall will help keep them from flexing.

This article was first featured at https://www.thingiverse.com/thing:4591543 on December 27, 2020 at 04:47PM by theeeemaster

More Stories

Can this possibly be true? “Metal 3D printing is now possible on any 3D printer…with the right settings and a few minor upgrades like a hardened steel nozzle…” – July 2 2023 at 04:59PM

New NASA Funding Ignites 25 3D Printing Projects in Space Exploration – June 18 2023 at 04:34PM

Nvidia AI produces 3D models from 2D videos 3D printing applications forthcoming? – June 15 2023 at 02:55AM