This Ventilator is an Experimental design done by Mitch Bahneman, a student of Mechanical Design at Chippewa Valley Technical College.

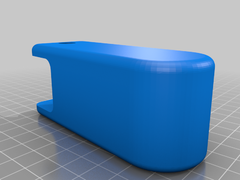

The design intent is to offer a mostly 3d printed, simple machine which will function as an emergency ventilator machine. It uses a basic adult sized BVM(bag valve mask), which are readily available and pumps it as a human hand would.

The electronics are simple and can be obtained for less than 100$.

It is printed in 8 parts and will take roughly 3-4 days, using about 1.5KG of filament.

I used PETG for strength but it might be possible to print in PLA or ABS aswell.

To ensure the most strength I suggest Printing with the following settings:

Ventilator Base

layer height .3mm, line count of 5 at the walls top and bottom. 20-30% cubic infill

Arm Split1 and Arm Split 2

layer height .3mm, line count 4 at the walls top and bottom, 30-40% cubic infill

Pump Base and Bag End dont need to be as strong, Layer height .3mm, line count 3, 20% infill.

Plunger layer height .3mm, line count 4 at the walls top and bottom, 30-40% cubic infill

Short Arm_V2 and Lng Arm_V2 Need to be strong, Layer height .3mm, 100% infill

Electronics List:

As this is still in the testing phase this list will not be fully complete yet.

Motor 2002-2005 Volkswagen Jetta windshield wiper motor

12 volt DC speed controller 6Amp rated

6Amp Power Supply

Arduino Uno

This article was first featured at https://ift.tt/3c9WQTP on April 10, 2020 at 10:55PM by rotaryprints

More Stories

Can this possibly be true? “Metal 3D printing is now possible on any 3D printer…with the right settings and a few minor upgrades like a hardened steel nozzle…” – July 2 2023 at 04:59PM

New NASA Funding Ignites 25 3D Printing Projects in Space Exploration – June 18 2023 at 04:34PM

Nvidia AI produces 3D models from 2D videos 3D printing applications forthcoming? – June 15 2023 at 02:55AM