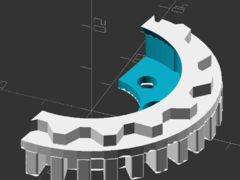

This camwheel has two functions: one is as a gear moved by two rotating pins and one is as camwheel to steer the zig-zag function of the sewing machine. It is a Vroom and Dreesmann type, that has been sold into the thousands in the Netherlands. Because a plastic wheel is mounted on a large metal piece, it breaks after some time because of ageing of the plastic and different expansion coefficient of the metal and the plastic. Likely similar machiness have been sold elsewhere. We (at saved tools Groningen) see this type of defect often, like in my previous camwheel design. Until recently we had to scrap these machines as replacing the broken camwheel was impossible: the shaft on which it is mounted cannot be taken out. So the wheel is printed in two different parts that are connected by a 3d printed connection with pins that fit into holes. Some hard PVC glue will hold it better together if required. If you are printing this wheel you have to flip the box that is present to cut the part in two pieces.

This article was first featured at https://ift.tt/3cFQn3Z on March 6, 2020 at 05:08PM by Gerardtem

More Stories

Can this possibly be true? “Metal 3D printing is now possible on any 3D printer…with the right settings and a few minor upgrades like a hardened steel nozzle…” – July 2 2023 at 04:59PM

New NASA Funding Ignites 25 3D Printing Projects in Space Exploration – June 18 2023 at 04:34PM

Nvidia AI produces 3D models from 2D videos 3D printing applications forthcoming? – June 15 2023 at 02:55AM