Update 28.03.2020

Added a Picture how to punch the A4 shield

Added a PDF as Template for the Shield

Added a .dxf for lasercutting

Update 27.03.2020 afternoon -> after coordination with “Deutsches Rotes Kreuz”

-> File: German-Standard_DRK_FaceShield_Mask_frame_C7.2_CR-3D.STL

-> the white one in the pictures

-> Series production for hospitals in Germany has started!!!

Changes:

- The visor was moved further away from the forehead – This allows a better fit over bigger respirators and protective goggles

- Total height set to 12mm -> for better wearing comfort

- better mounting of the rubber band and for easier printing (Downskin)

- Overall length has been reduced

Important:

We made these changes together with the Deutsches Rotes Kreuz (DRK) and these were found to be good for Germany.

So we set this shield as the standard for Germany!

- At least 0.3 mm was used as the film thickness.

- An additional mounting of the shield by a bottom frame was not considered important, which is why this will be dispensed with in the future.

- On the inside of the forehead support we use a foam tape to further improve comfort

- the DIN A4 shield does not have to be the entire length. it is recommended to shorten the shield by approx. 50mm in order to be able to turn the head even better with the shield

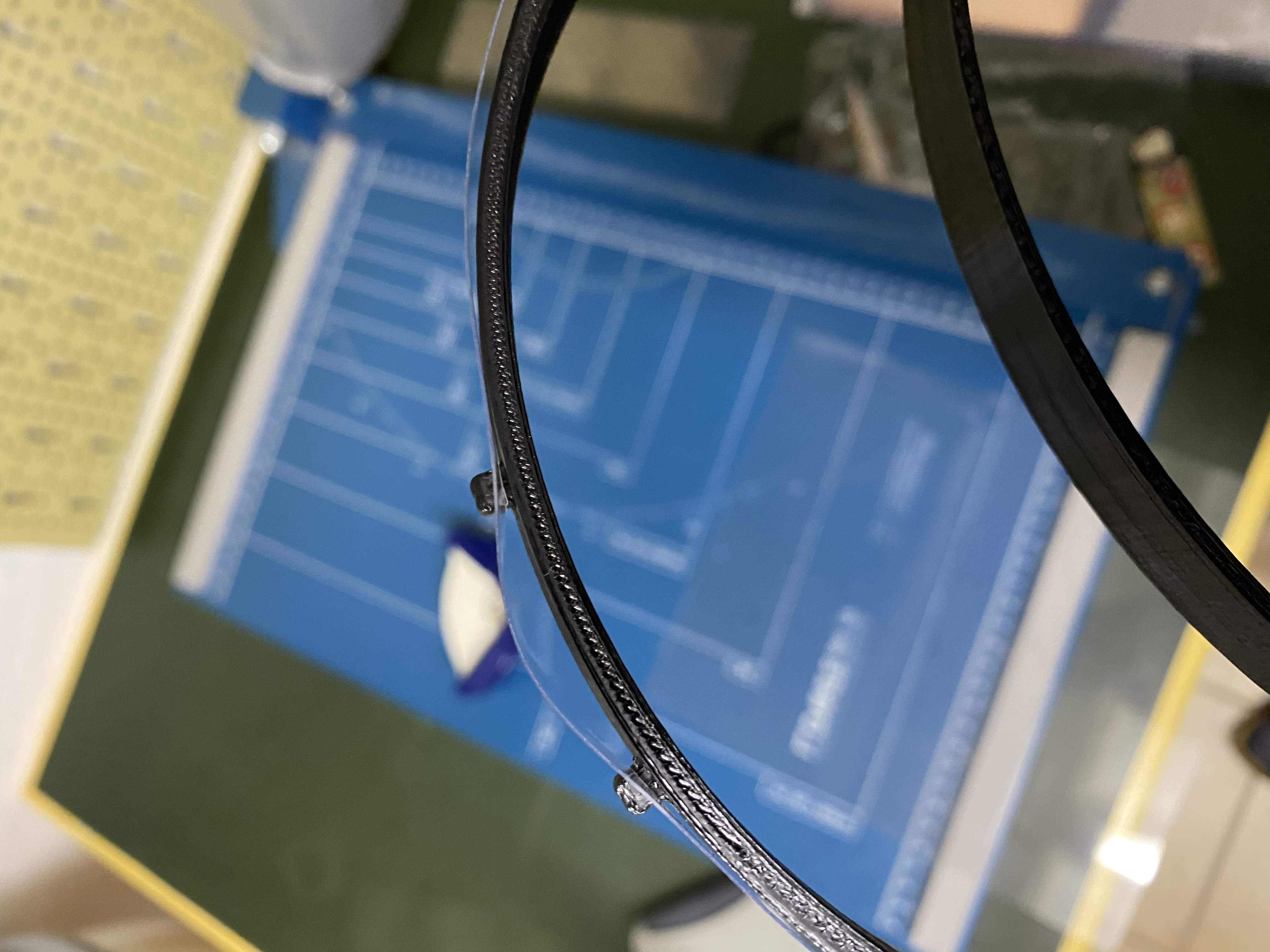

you can use a simple A4 sheet cover and a conventional punch! just keep a distance of 9mm from the edge so that the film can be pulled tight -> These must be attached as in the attached picture.

For example, we use the following sheets:

https://www.falambi.de/einbanddeckel/din-a4/100-deckelfolien-din-a4-transparent-klar?number=25006

The following was used as a rubber band:

https://www.amazon.de/gp/product/B01LZE7IEN/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

Update 26.03.2020 – Afternoon

Added a stack with 6 shields -> there is a gap with 0,2mm between the parts

Update 26.03.2020 – Lunch

Changed the Belt Holder on the back side

-> Mask_frame_C5_CR-3D.stl

Update 26.03.2020

I will order and test a thicker film (0.3mm)!

Added a new Version -> Mask_frame_C4_CR-3D.stl

Changelog:

- The height was reduced by 2mm

- the thickness has been adjusted

- the cover plate has been removed (Would be optional but possible)

Added different bottom frames for different shield thickness

-> for a 0,2mm Shield the 0,3mm bottom frame works fine for me!

Old Version -> Mask_frame_C3_CR-3D-small-file.stl

We have been receiving more and more requests for so-called face shields in the past few days, which is why we have developed a variant that has been optimized for us:

Important:

The design was based on that of PRUSA, but I completely redesigned and designed it and, in my opinion, incorporated a few updates. I didn’t have the initial idea for such a face shield, Josef PRUSA had it, but I changed it by a few points.

For one thing, I completely closed the gap between the shield and the head with a base plate.

I have optimized the file regarding printing time. I removed all senseless openings and I reduced the height and was able to reduce the printing time significantly

Another very big advantage:

With our variants, you can use a simple A4 sheet cover and drill the 4 holes with a conventional punch. These must be attached as in the attached picture.

For example, we use the following sheets:

https://www.falambi.de/einbanddeckel/din-a4/100-deckelfolien-din-a4-transparent-klar?number=25006

The following was used as a rubber band:

https://www.amazon.de/gp/product/B01LZE7IEN/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

So anyone who owns a 3D printer can easily produce and provide such a shield. Please share this design, improve it and produce it for everyone who needs it.

Version C3:

You can use standard DIN A4 Sheets and a conventional punch for creating the shield itself.

If you want to manufacture shields for others PLEASE READ THIS CAREFULLY

Act as if you were infected by the COVID-19 virus.

Wear a face mask and a fresh pair of gloves when collecting each batch of printed parts. Store the parts immediately in a sealable bag.

Talk with whoever you’re making the shields for, let them know about your manufacturing environment

There is still debate about how long the virus survives on plastic, but most sources mention 2-3 days. That means that by letting the packed face shields sit for 2-3 days before distributing them, you’ll greatly reduce risk of transmission

Do not store the entire stock in one place, minimize the risk of cross contamination

Source Josef PRUSA

This article was first featured at https://ift.tt/3bqvuIC on March 28, 2020 at 03:35PM by CR-3D_official

More Stories

Can this possibly be true? “Metal 3D printing is now possible on any 3D printer…with the right settings and a few minor upgrades like a hardened steel nozzle…” – July 2 2023 at 04:59PM

New NASA Funding Ignites 25 3D Printing Projects in Space Exploration – June 18 2023 at 04:34PM

Nvidia AI produces 3D models from 2D videos 3D printing applications forthcoming? – June 15 2023 at 02:55AM